1. Material Preparation: In a spacious and well-lit studio, artisans commence their craft. They meticulously select the highest quality high borosilicate glass blocks, which glisten with clarity under the morning sunlight. This process is akin to selecting precious gemstones, ensuring that only the purest glass blocks are chosen to guarantee the absence of impurities in the final product.

2. Glass Block Preheating: The glass blocks need to be preheated to ensure even heating during the blowing process. This scene is filled with subtle temperature variations, starting from the surface of the glass block, where warm air gently diffuses to ensure uniformity. It’s as if a greenhouse environment is being created for the birth of an art piece, ensuring that the glass material isn’t subjected to uneven heat.

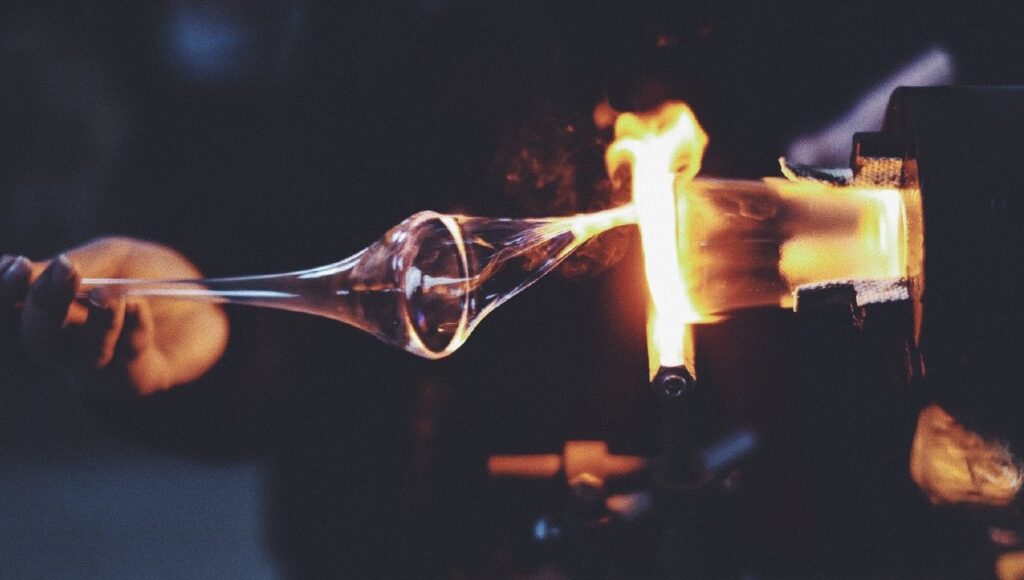

3. Blowing the Glass Blank: On a well-equipped workbench, artisans delicately blow air into a metal blowpipe while gently rotating the glass block. This is a highly skillful process; their eyes are fixed on the glass blank, and their arm and hand movements are fluid and precise. Their breath and actions are synchronized, shaping the glass blank into the desired vessel form. This scene resembles a magnificent dance, with each movement a flawless performance.

4. Shaping and Embellishing: Once the basic shape is determined, artisans use specialized tools and molds to further shape and embellish the glassware. In this scene, artisans hold tools, gently stretch, emboss, trim, and engrave the glass, giving the vessel a distinctive appearance and texture. This is a scene brimming with creativity and unique design, where each action is imbued with the artisan’s inspiration.

5. Cooling and Annealing: After shaping and decoration, the glassware needs to undergo a slow cooling process, usually within a specialized annealing oven. This scene is characterized by calmness and waiting. Artisans know that this step is crucial to prevent internal stress in the glassware, enhancing its strength and heat resistance.

6. Inspection and Quality Control: The finished glassware is meticulously examined on a brightly lit inspection table. Artisans scrutinize each vessel with a professional eye, checking for cracks, bubbles, or any other defects. This is a precise and detailed scene, where only flawless products pass the inspection.

7. Cleaning and Packaging: The final high borosilicate glassware undergoes thorough cleaning and packaging to ensure they remain clean and intact during transportation and sale. This is an orderly and neat scene, guaranteeing that customers receive a perfect product.

The entire process is filled with professional craftsmanship and artistic creativity, and artisans showcase their exceptional skills throughout. This craft scene emphasizes the high quality, exquisite craftsmanship, and uniqueness of glassware, making them an indispensable part of high-end dining, baking, and cooking scenarios.